How to pick a pump to do the best job and not leak

Thread, straw & doze: how to pick a pump to do the best job and not leak.

Golden rule first:

There’s no perfect pump, only properly tested. Eve if all the parameters are matched perfectly on paper, the final score can be given only after real testing is done – with every batch, preferably.

Three main features to look at when choosing a pump:

the thread, dosage, and length of the straw.

Neck and thread.

The thread is what we call the material on the outside of the bottle’s neck, or the inner size of the cap. By default, the thread size is written with a slash or an affix: 24/410, 24-410. The first number (24) stands for size of the thread in millimeters, the latter shows, how many coils the thread does around the neck.

Measuring the thread.

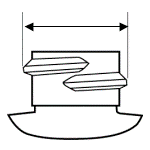

Bottle’s neck thread size is measured from on edge to the opposite diametrically. Apparently, in the distance between the edges is 24 mm, the inner size of the closure must be the same.

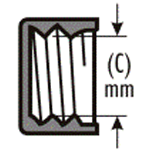

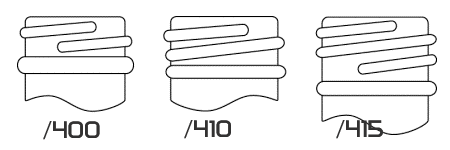

The cap’s size is measured from one inner wall to the other: Digits after the slash reflects the number of coils around the neck. If the thread winds around the neck once, the code for it is 400. If it winds around 1,5 times – 410. Two full turns – 415, and so on. Most common coils are 410 and 415 – 1 or 1,5 full turns.

Tightness

Air tightness and margin tolerance – what may go wrong? Matching digits of the cap’s and the bottle’s marking, unfortunately, does not guarantee full tightness of the pair. Each manufacturer uses his own allowance, so the resulting gap clearance may be up to a full millimeter. The only way out is testing. Preferably for every batch.

In some cases a neck with higher index of thread turns may be successfully applied with a cap of smaller thread index. For example, a 24/410 cap can sit on a 24/415 bottle neck. But never vice versa. In such case the set can even perform decent air-tightness, though, only testing can tell.

Dosage.

Pumps have two most common categories: lotion pumps, mostly used with products, that require larger doses for a sing use, like shampoo, liquid soap, shower gel, body lotion, etc. Such pumps mainly go with 150ml or bigger bottles and give out about 1.5 to 5 ml per press.

Type two is cream pumps with much smaller dosage for point application: face cream, serum, make-up and alike. Mostly used with bottles of under 150ml capacity and dosing from 0.1 up to 1.5 ml per press.

Another key point in terms of dosing is the product’s viscosity and hard particles content.

Most of the pumps are designed to deal with creamy or gel-like products. Pumps and other dispensers for thin or the other way around clayish substances have their own marking usually accentuated by the manufacturer. In such a case there’s no way to just pick a closure of the same size as the bottle’s neck – when making an inquiry, mentioning the product’s extremely high or low viscosity is necessary. The best idea for extra-thin and watery products, though, is using a disc-top cap or a dropper instead.

Same things about hard particle content products. With higher dosage around 5ml problems are scarce, though, when it goes to cream pumps things get a lot more complicated, as most of such pumps are not designed to allow unhindered flow of substances containing hard particles. Just like with extra high/low viscosity pumps, there’s a separate category for microbeads. So, when making an inquiry, particle content in the product should be mentioned along with the formula’s viscosity.

The straw.

A perfect straw for a thin product is a soft and just long enough to make a slight curve on the bottle’s bottom. For thicker formulas – a hard one pointing straight at the bottom leaving a slight clearance. Maintaining such features will make sure the pump doesn’t spit and drains the maxim amount of the product out of the container. If the straw is shorter then necessary,

the system will only work more or less correctly only while the bottle is full. As soon as part of the content is extracted, the dispenser starts pumping the air instead of the products.

Too long a straw mainly results in two kinds of malfunctioning.

If the straw is shoved tight into the bottom, the orifice gets block from the content and the air, making it impossible to raise enough pressure inside the system. Besides, if the straw is hard and strongly pressing the bottom, the bottom starts arching outside and the bottle loses its steadiness.

If the straw is soft and too long, it coils on the bottom, so the leftovers of the product (especially a thick one), stay spread on the walls and the bottom of the bottle having no chance of getting extracted. In case of more fluent products like liquid soap shower gels, the problem is solvable just by leaning the bottle to make the product slip off to the straw’s orifice. Yet when it comes to thicker creams, body lotions and butters, every drop extracted will first take a bunch of shaking and scrambling. Or going the old-fashioned way by taking off the pump and raking out the leftovers with the straw by hand.